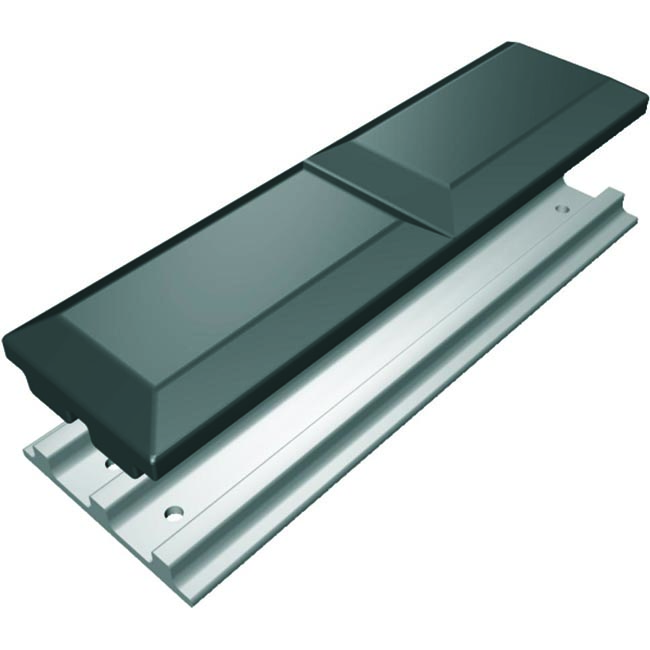

Excavator rubber feet, also known as excavator rubber track pads, play a vital role in the performance and longevity of your excavator. These rubber pads are designed to provide traction, reduce ground damage and enhance the overall stability of the excavator. As the construction and mining industry continues to grow, the demand for high-quality excavator rubber mats continues to increase. In this article, we will explore the market positioning and development direction of excavator rubber blocks to understand its significance in the industry.

Market positioning:

The growing demand for efficient and sustainable construction equipment is driving the excavator rubber pads market. To minimize environmental impact and maximize productivity, construction companies are looking for durable and reliable rubber pads for their excavators. The market positioning of excavator rubber mats focuses on their ability to provide excellent traction, reduce noise levels and protect fragile surfaces, making them an essential component on a variety of construction and excavation projects.

Furthermore, the demand for excavator rubber pads is influenced by the growing trend of using rubber tracks instead of traditional steel tracks. Rubber tracks offer several benefits, including reduced ground pressure, improved maneuverability and improved operator comfort. Therefore, excavator rubber mats have gained huge traction in the market and are positioned as a cost-effective solution to enhance the performance and versatility of excavators in different terrains and applications.

Direction of development:

In line with the ever-changing needs of the construction industry, developments in excavator rubber blocks are focused on enhancing their durability, versatility and environmental sustainability. Manufacturers are investing in research and development to create advanced rubber pad designs that can withstand heavy loads, extreme weather conditions and long-term use. This includes the use of high-quality rubber compounds, innovative tread patterns and advanced bonding technology to ensure optimal performance and longevity.

In addition, the development direction of excavator rubber pads is consistent with the industry’s emphasis on environmentally friendly solutions. Sustainable manufacturing practices, such as using recycled materials and reducing carbon footprints, are becoming integral to rubber mat production. This not only solves environmental concerns but makes excavator rubber mats a responsible choice for construction companies looking to minimize their ecological impact.

In addition, the development direction of excavator rubber blocks includes customization and adaptability to meet the specific requirements of different excavator models and applications. Manufacturers strive to offer a variety of sizes, shapes and configurations to ensure compatibility with a variety of equipment and operating conditions. This flexibility allows construction companies to optimize excavator performance based on the specific needs of each project.

In short, the market positioning and development direction of excavator rubber pads highlight their importance in the construction and mining industries. As the demand for efficient, sustainable and high-performance equipment continues to grow, excavator rubber mats will play a key role in enhancing the capabilities of excavators and contributing to the overall productivity and environmental responsibility of construction operations. As designs, materials and manufacturing processes continue to advance, excavator rubber mats will continue to be an important part of the growing construction equipment sector.

Post time: Mar-29-2024