Excavator rubber pads play a vital role in the construction and mining industries, providing traction, stability and protection to machines and the ground they run on. As technology continues to advance, the future direction of excavator rubber mats promises significant improvements in performance, durability and environmental sustainability.

One of the key areas for future development of track pad excavator is the integration of advanced materials and manufacturing technology. The use of high-quality, durable rubber compounds and innovative manufacturing processes will result in brake pads with superior wear resistance, longer service life and enhanced performance under a variety of operating conditions. In addition, the development of composite materials and advanced bonding technology will further improve the overall strength and reliability of rubber pads, ensuring that they can withstand heavy loads and harsh environments.

Another important aspect of the future development of excavator pads is the focus on environmental sustainability. As awareness of environmental issues continues to grow, the demand for eco-friendly construction and mining practices continues to grow. In response to this, future rubber mat designs will prioritize the use of recyclable materials and reduce the carbon footprint of the production process. This is not only good for the environment but also in line with the sustainability goals of construction and mining companies.

In addition, the future development direction of excavator rubber pads will also involve the integration of intelligent technology. Advances in sensor technology and data analytics will lead to the development of smart rubber pads that can provide real-time feedback on their condition, wear and performance. This will allow for proactive maintenance and replacement, ultimately reducing downtime and improving overall operational efficiency.

In addition to advances in materials and technology, the future development of excavator rubber feet will also focus on customization and adaptability. As construction and mining projects become more diverse and complex, the need for rubber mats that can be customized to specific machine models and ground conditions will continue to grow. Customizable designs and modular components will allow operators to optimize excavator performance, resulting in increased productivity and cost savings.

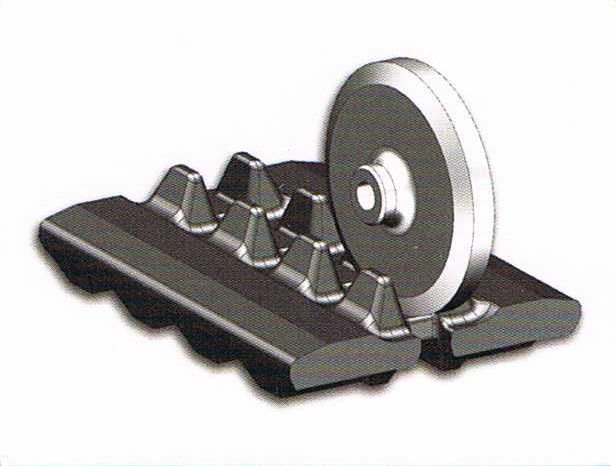

In addition, the future direction of excavator rubber foot pads will also involve enhanced safety features. The combination of advanced anti-slip patterns, noise reduction technology and improved shock absorption technology will provide operators with a safer working environment and reduce the impact on the surrounding area.

Taken together, the future direction of excavator rubber feet will bring significant advancements in performance, durability and environmental sustainability. By leveraging advanced materials, smart technology, customization and safety features, next-generation rubber mats will deliver greater efficiency, reduced environmental impact and enhanced safety for construction and mining operations. As the industry continues to evolve, these developments will play a vital role in meeting the growing demand for more efficient and sustainable construction and mining practices.

Post time: Apr-07-2024