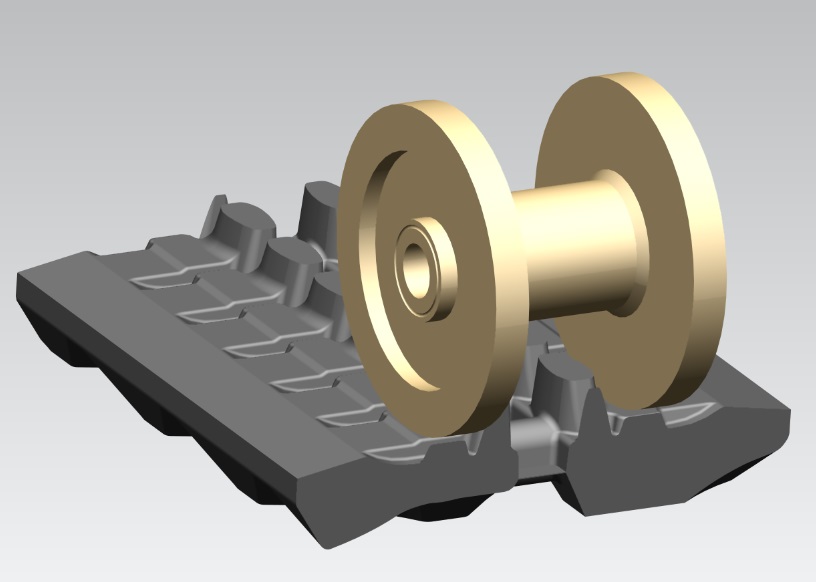

Excavator track pads, also known as excavator pads or digger track pads, offer numerous benefits that enhance your machine’s performance and efficiency. Rubber track pads for excavators serve as a protective barrier between the metal tracks and the ground, minimizing damage to surfaces like roads and pavements. By using these rubber track pads, you can enjoy improved traction and reduced noise, which leads to better fuel efficiency. Additionally, these pads decrease wear and tear on both the tracks and the surfaces they operate on. As a result, you experience less maintenance and longer-lasting equipment, making them a versatile choice for various terrains and industries.

Performance Benefits of Excavator Track Pads

When you choose rubber track pads for excavators, you unlock a range of performance benefits that enhance your machine’s capabilities. These benefits not only improve the efficiency of your operations but also contribute to the longevity of your equipment.

Enhanced Efficiency of Excavator Pads

Improved Traction and Stability

Rubber track pads provide superior traction compared to traditional steel tracks. This enhanced grip ensures that your excavator maintains stability, even on challenging terrains. Whether you’re working on wet, soft ground or uneven surfaces, these pads help prevent slippage and ensure precise maneuverability. The improved traction also reduces the risk of accidents, making your work environment safer.

Smoother Operation

With rubber track pads, you experience a smoother operation. The pads absorb shocks and vibrations, minimizing the impact on both the machine and the operator. This reduction in vibration not only enhances comfort but also decreases wear and tear on the excavator components. As a result, you enjoy a quieter and more efficient working experience, which can lead to better fuel efficiency and reduced operational costs.

Longevity of Digger Track Pads

Reduced Wear and Tear

Rubber track pads act as a protective layer between the metal tracks and the ground. This protection significantly reduces wear and tear on both the tracks and the surfaces they traverse. By minimizing surface damage, you extend the lifespan of your equipment and reduce the frequency of repairs. This durability makes rubber track pads a cost-effective choice for long-term use.

Extended Lifespan of Tracks

The longevity of digger track pads is one of their most appealing features. High-quality rubber pads withstand harsh operating conditions, ensuring reliability even in demanding environments. Unlike traditional steel tracks, which may wear out faster, rubber track pads maintain their integrity over time. This extended lifespan translates to fewer replacements and lower maintenance costs, ultimately saving you money and enhancing your project’s profitability.

Cost-Effectiveness of Rubber Track Pads for Excavators

Choosing rubber track pads for your excavators can significantly reduce costs, making them a smart investment for your operations. These pads not only lower maintenance expenses but also minimize downtime, enhancing your overall productivity.

Lower Maintenance Costs

Decreased Frequency of Repairs

Rubber track pads for excavators offer a durable solution that reduces the need for frequent repairs. Unlike traditional steel tracks, these pads absorb shocks and vibrations, which minimizes wear and tear on both the tracks and the surfaces they traverse. This durability means you spend less time and money on repairs, allowing you to allocate resources more efficiently.

Cost Savings on Replacement Parts

With rubber track pads, you enjoy cost savings on replacement parts. The longevity of these pads means fewer replacements over time. High-quality rubber pads withstand harsh conditions, ensuring reliability and reducing the need for frequent part replacements. This translates to significant savings, allowing you to invest in other areas of your business.

Reduced Downtime

Increased Operational Time

Rubber track pads enhance your excavator’s operational time by minimizing downtime. Their durability and ease of installation mean you can quickly transition between job sites without lengthy delays. This increased operational time allows you to complete projects more efficiently, maximizing your equipment’s productivity.

Faster Project Completion

By reducing downtime, rubber track pads contribute to faster project completion. You can maintain a steady workflow without interruptions caused by equipment repairs or replacements. This efficiency not only improves your project’s timeline but also enhances client satisfaction, as you deliver results promptly.

Incorporating rubber track pads into your excavator operations offers numerous cost-effective benefits. From lowering maintenance costs to reducing downtime, these pads provide a reliable and efficient solution for your heavy equipment needs.

Versatility of Excavator Track Pads

Rubber track pads for excavators offer remarkable versatility, making them an ideal choice for various terrains and industries. Their adaptability and wide-ranging applicability ensure that you can rely on them for diverse projects and environments.

Adaptability to Various Terrains

Suitable for Urban and Rural Areas

Excavator track pads excel in both urban and rural settings. In urban areas, these pads minimize ground disturbance, protecting delicate surfaces like asphalt and concrete. This feature is crucial for maintaining infrastructure integrity and reducing repair costs. In rural areas, the pads provide stability on uneven and soft terrains, ensuring efficient operation without damaging the natural landscape.

Effective on Soft and Hard Surfaces

Rubber track pads adapt seamlessly to different surface types. On soft surfaces, they distribute the weight of the excavator evenly, preventing sinking and preserving the ground. On hard surfaces, they offer excellent traction, reducing slippage and enhancing maneuverability. This adaptability makes them a reliable choice for any job site, regardless of the terrain.

Applicability Across Industries

Construction and Demolition

In the construction and demolition sectors, digger track pads play a vital role. They protect surfaces from damage caused by heavy machinery, ensuring that roads and pavements remain intact. This protection reduces the need for costly repairs and enhances safety for workers and pedestrians. Additionally, the reduced noise levels from rubber pads contribute to a more pleasant working environment.

Landscaping and Agriculture

For landscaping and agriculture, rubber track pads for excavators provide significant benefits. They minimize turf damage, preserving the aesthetic and functional quality of the land. In agriculture, these pads allow machinery to operate efficiently on soft soil without compacting it, promoting healthy crop growth. Their versatility ensures that you can tackle various tasks without compromising the land’s integrity.

Scientific Research Findings: Studies highlight the growing demand for eco-friendly and recyclable rubber track pads, driven by sustainable construction practices. These pads not only reduce environmental impact but also enhance operational efficiency across industries.

By choosing rubber track pads, you embrace a versatile solution that meets the demands of diverse terrains and industries. Their adaptability and protective features make them an invaluable asset for your excavator operations.

Safety and Environmental Impact of Rubber Track Pads for Excavators

Rubber track pads for excavators offer significant safety and environmental benefits. By choosing these pads, you not only protect the surfaces you work on but also enhance the safety of your operations.

Minimization of Surface Damage

Protection of Pavements and Roads

Rubber track pads act as a cushion between the metal tracks and the ground. This cushioning effect protects pavements and roads from the heavy impact of machinery. Without these pads, metal tracks can dig into surfaces, creating ruts and trenches. Such damage can lead to costly repairs and pose hazards to workers and pedestrians. By using rubber track pads, you maintain the integrity of infrastructure, ensuring safer and more durable surfaces.

Preservation of Natural Landscapes

When working in natural environments, preserving the landscape is crucial. Rubber track pads distribute the weight of the excavator evenly, reducing ground disturbance. This feature is especially beneficial in sensitive areas where minimizing environmental impact is a priority. By preventing deep impressions and soil compaction, you help preserve the natural beauty and functionality of the land.

Assurance of Operator Safety

Enhanced Control and Maneuverability

Rubber track pads provide superior traction, which enhances control and maneuverability. This improved grip allows you to navigate challenging terrains with ease. Whether you’re operating on wet or uneven surfaces, these pads help prevent slippage. Enhanced control not only boosts your efficiency but also ensures a safer working environment.

Reduced Risk of Accidents

Safety is paramount in any operation. Rubber track pads absorb shocks and vibrations, reducing the strain on both the machine and the operator. This absorption leads to smoother operation and less fatigue for you. By minimizing vibrations, you decrease the likelihood of accidents caused by equipment instability. The quieter operation also contributes to a more pleasant and focused work environment.

Sustainability Note: The demand for eco-friendly rubber track pads is rising. These pads not only reduce noise and vibration but also align with sustainable construction practices. By choosing environmentally friendly materials, you contribute to a greener future while enhancing your operational efficiency.

Incorporating rubber track pads into your excavator operations provides a dual benefit. You protect the environment and ensure the safety of your team. These pads represent a smart choice for those committed to sustainable and safe construction practices.

Rubber track pads offer numerous benefits for your excavator operations. They enhance traction, reduce noise, and improve fuel efficiency, making them a smart choice for any project. By choosing rubber track pads, you enjoy cost savings through decreased wear and tear on surfaces and equipment. These pads also contribute to a safer work environment and minimize environmental impact. Consider adopting rubber track pads to boost your excavator’s performance and ensure efficient, sustainable operations. Embrace this innovative solution to meet the demands of modern construction and infrastructure projects.

Post time: Nov-14-2024