Manufacturer for Shandong Mini Excavator 1.6 Ton Rubber Tracks for Mini Excavator 1600kg Digger

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Manufacturer for Shandong Mini Excavator 1.6 Ton Rubber Tracks for Mini Excavator 1600kg Digger, Trust us, you’ll obtain a greater answer on car pieces industry.

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for China Smallest Mini Excavator and Mini Digger, You can allow us to know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

About Us

We pursue the administration tenet of “Quality is exceptional, Provider is supreme, Name is first”, and will sincerely create and share success with all clientele for Wholesale Excavator Rubber, We goal at Ongoing system innovation, management innovation, elite innovation and sector innovation, give full play for the overall advantages, and constantly make improvements to support excellent. We are looking forward that more and more oversea friends join in our family for further development near the future!

We have a highly efficient team to deal with inquiries from customers. Our goal is “100% customer satisfaction by our product quality, price & our team service” and enjoy a good reputation among clients. With many factories, we can provide a wide range of Free sample for Rubber Tracks 300×55.5 Excavator Tracks,Please ship us your specifications and demands, or truly feel totally free to get hold of us with any questions or inquiries that you may have.

Specification:

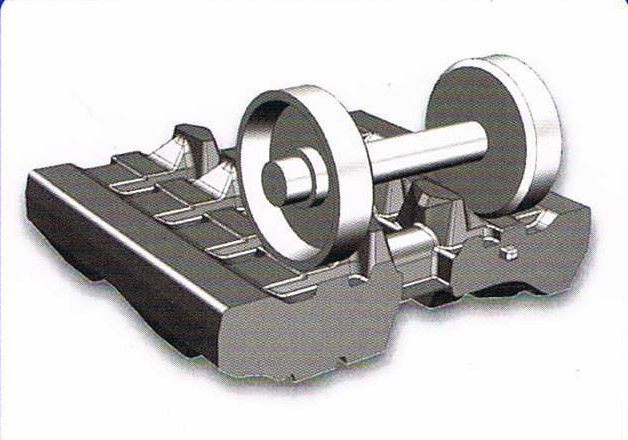

Our 300×55.5 conventional rubber tracks are for use with undercarriages of machinery specifically designed to operate on rubber tracks. Conventional rubber tracks do not make contact with the metal of the equipment’s rollers while in operation. No contact equals increased operator comfort. Another advantage of conventional rubber tracks is the heavy equipment roller contact will ONLY occur when aligning the conventional rubber tracks to prevent roller derailment.

Production Process

Raw Material: Natural rubber / SBR rubber/ Kevlar fiber / Metal / Steel cord

Step: 1.Natural rubber and SBR rubber mixed together with special ratio then they will be formed as

rubber block

2.Steel cord coverd with kevlar fibe

3.Metal parts will be injected with special compounds which can improve their performance

3.The rubber block , kevlar fiber cord and metal will be put on the mould in ordered

4.The mould with materials will be deliver in to the big production machine, the machinery use high

temperature and high volume press to make all the material together.

Shipping Package

We have pallets+black plastic wrapping around packages for LCL shipping goods.For full container goods, usually bulk package.