IOS Certificate Track Shoe for Excavator Track Pads Track Link Chain

Sticking to the principle of “Super Good quality, Satisfactory service” ,We are striving to become an excellent organization partner of you for IOS Certificate Track Shoe for Excavator Track Pads Track Link Chain, We play a leading role in supplying clients with high-quality items very good provider and competitive price ranges.

Sticking to the principle of “Super Good quality, Satisfactory service” ,We are striving to become an excellent organization partner of you for China Track Link and Link Shoe, In order to meet our market demands, we now have paied more attention to the quality of our solutions and services. Now we can meet customers’ special requirements for special designs. We persistently develop our enterprise spirit “quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

About Us

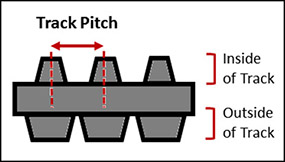

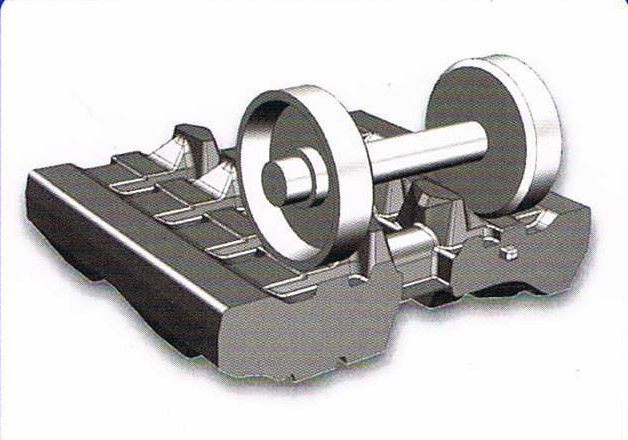

Our 400-72.5KW conventional rubber tracks are for use with undercarriages of machinery specifically designed to operate on rubber tracks. Conventional rubber tracks do not make contact with the metal of the equipment’s rollers while in operation. No contact equals increased operator comfort. Another advantage of conventional rubber tracks is the heavy equipment roller contact will ONLY occur when aligning the conventional rubber tracks to prevent roller derailment.

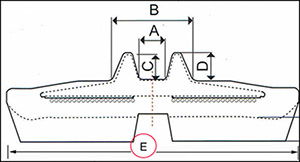

Our rubber tracks are made from specially formulated rubber compounds that resist cutting and tearing. Our tracks have all-steel links that are designed with exact guide specifications to fit your machine and ensure smooth equipment operation. The steel inserts are drop-forged and are dipped in a special bonding adhesive. By dipping the steel inserts rather than brushing them with adhesive there is a much stronger and more consistent bond within; This ensures a more durable track.

Purchasing rubber tracks for your equipment from us can increase the versatility of the functions that your machine can perform. In addition, replacing your old rubber tracks with new ones from ensures peace of mind that you won’t have machine downtime – saving you money and getting your job done on time.ronger and more consistent bond within; This ensures a more durable track.

Specification:

| Track width | Pitch Length | Number of Links | Guiding type |

| 400 | 72.5 | 68-92 | B2 |

Production Process

Raw Material: Natural rubber / SBR rubber/ Kevlar fiber / Metal / Steel cord

Step: 1.Natural rubber and SBR rubber mixed together with special ratio then they will be formed as

rubber block

2.Steel cord coverd with kevlar fibe

3.Metal parts will be injected with special compounds which can improve their performance

3.The rubber block , kevlar fiber cord and metal will be put on the mould in ordered

4.The mould with materials will be deliver in to the big production machine, the machinery use high

temperature and high volume press to make all the material together.

1 inch = 25.4 millimeters

1 millimeter = 0.0393701 inches

Product Warranty

All our rubber tracks are made with a serial Number, we may trace the product date against the serial Number.

It’s normally 1year factory warranty from production date, or 1200 working hours.