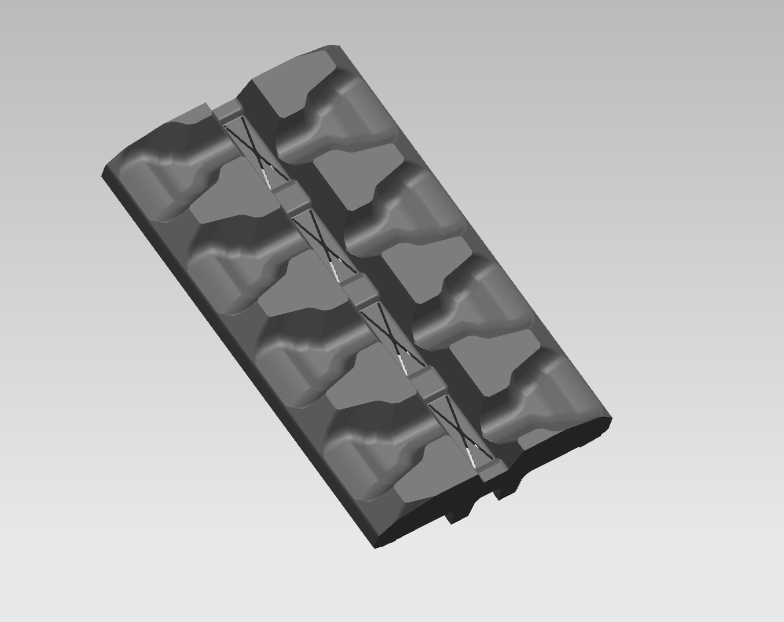

Excavator rubber track pads RP400-135-R2

Excavator track pads RP400-135-R2

Maintenance Methods:

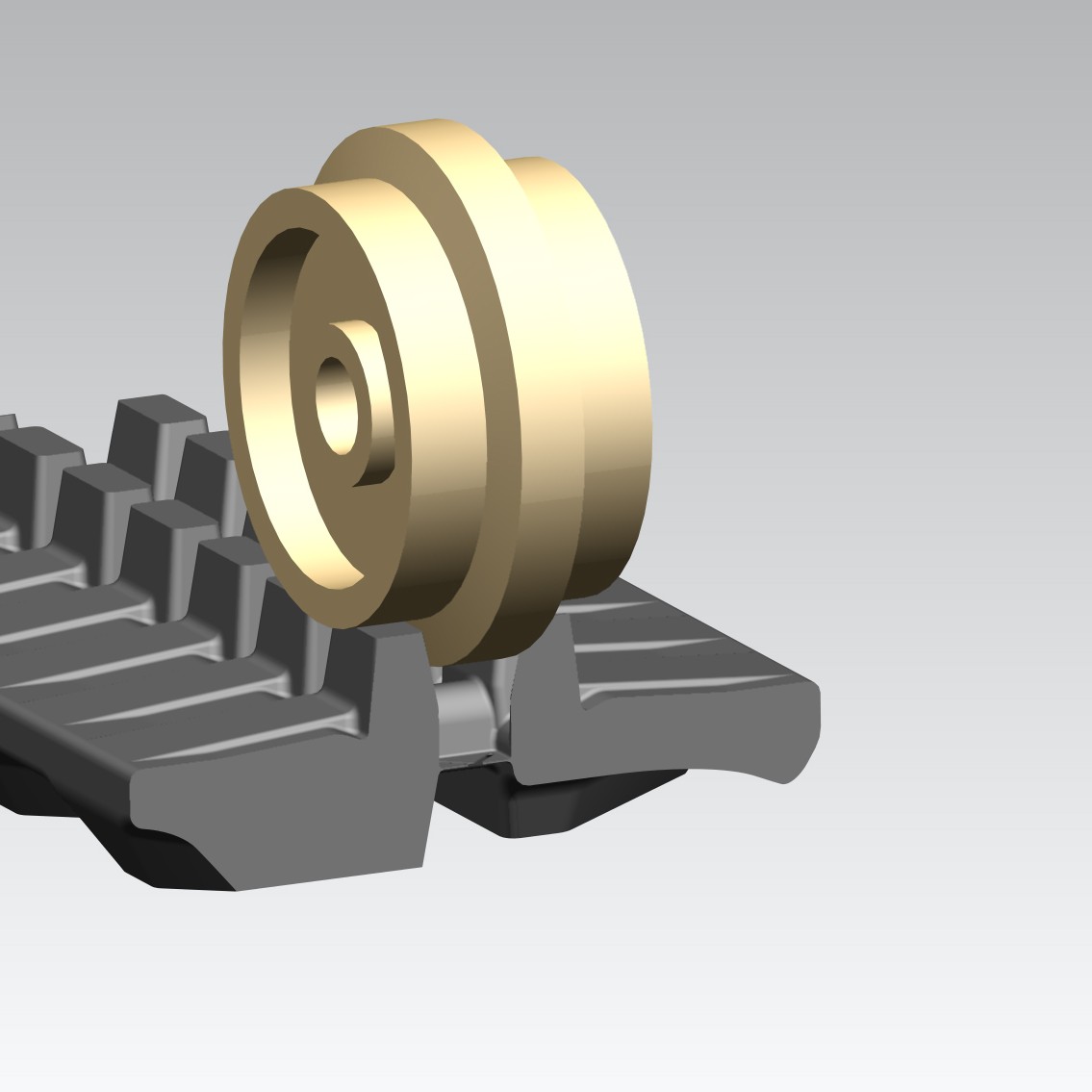

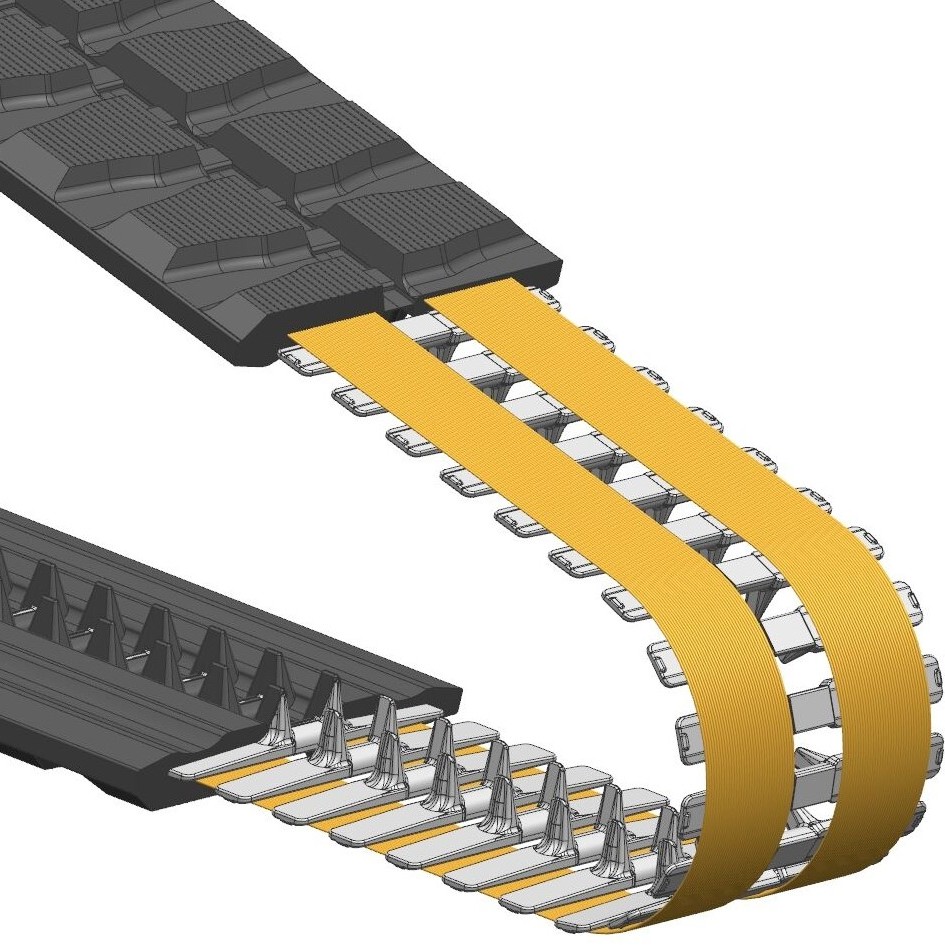

Regular Inspection: It is essential to inspect the track pads regularly for signs of wear and tear. Look for any damage, such as cuts, tears, or excessive wear, and replace the track pads as needed to prevent further damage to the rubber tracks.

Proper Storage: When not in use, store the excavator track pads in a clean, dry environment to prevent deterioration. Avoid exposure to direct sunlight, extreme temperatures, and chemicals that can degrade the rubber material.

Lubrication: Apply a suitable lubricant to the track pads to reduce friction and wear. This helps prolong the life of the track pads and ensures smooth operation of the excavator’s rubber tracks.

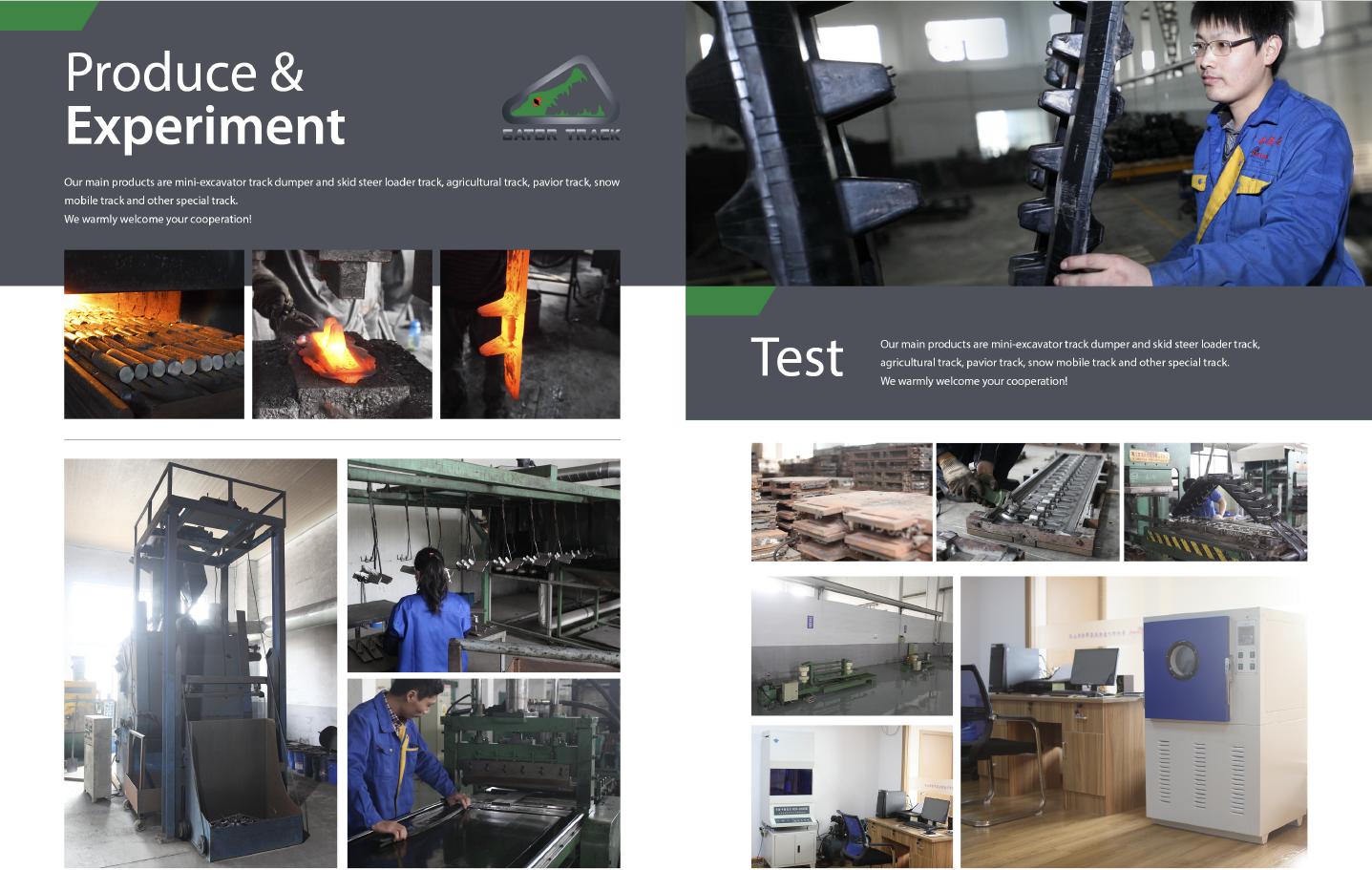

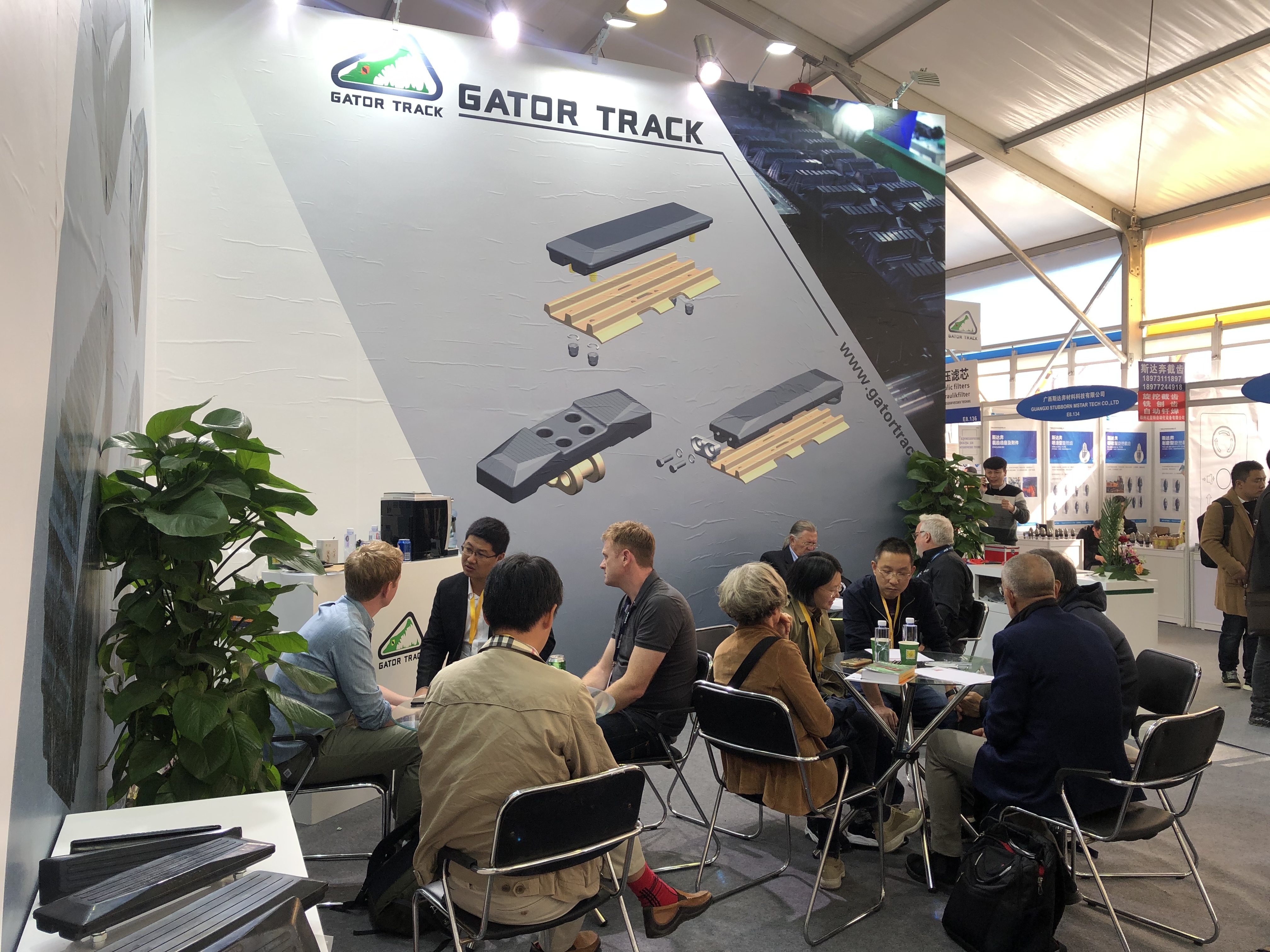

Founded in 2015, Gator Track Co., Ltd, is specialized in manufacturing rubber tracks and rubber pads. Production plant locates at No. 119 Houhuang, Wujin District, Changzhou, Jiangsu Province. We are happy to meet customers and friends from all parts of the world, it is always joyful to meet in person!

We currently have 10 vulcanization workers, 2 quality management personnel, 5 sales personnel, 3 management personnel, 3 technical personnel, and 5 warehouse management and container loading personnel.

Currently, our production capacity is 12-15 20 feet containers of rubber tracks per month. Annual turnover is US$7 million

1. What is your minimum order quantity?

We do not have a certain quantity requirement to start, any quantity is welcome!

2. How long is the delivery time?

30-45 days after order confirmation for 1X20 FCL.

3. Which port is closest to you?

We usually ship from Shanghai.

4. What information should I offer to confirm a size?

A1. Track Width * Pitch Length * Links

A2. Your machine type (Like Bobcat E20)

A3. Quantity, FOB or CIF price, port

A4. If it is possible, pls also provide with pictures or drawing for double checking.