Excavator Rubber Pads

Excavator rubber pads are an important part of any excavator machine. They play a vital role in providing traction, stability and support for machine movement over a variety of terrains. Rubber track pads for excavators are a popular choice due to their durability, noise reduction, and minimal impact on the road surface. When it comes to excavator track pads, quality is crucial. Choosing high-quality rubber pads for your excavator can significantly improve the performance and longevity of your excavator.

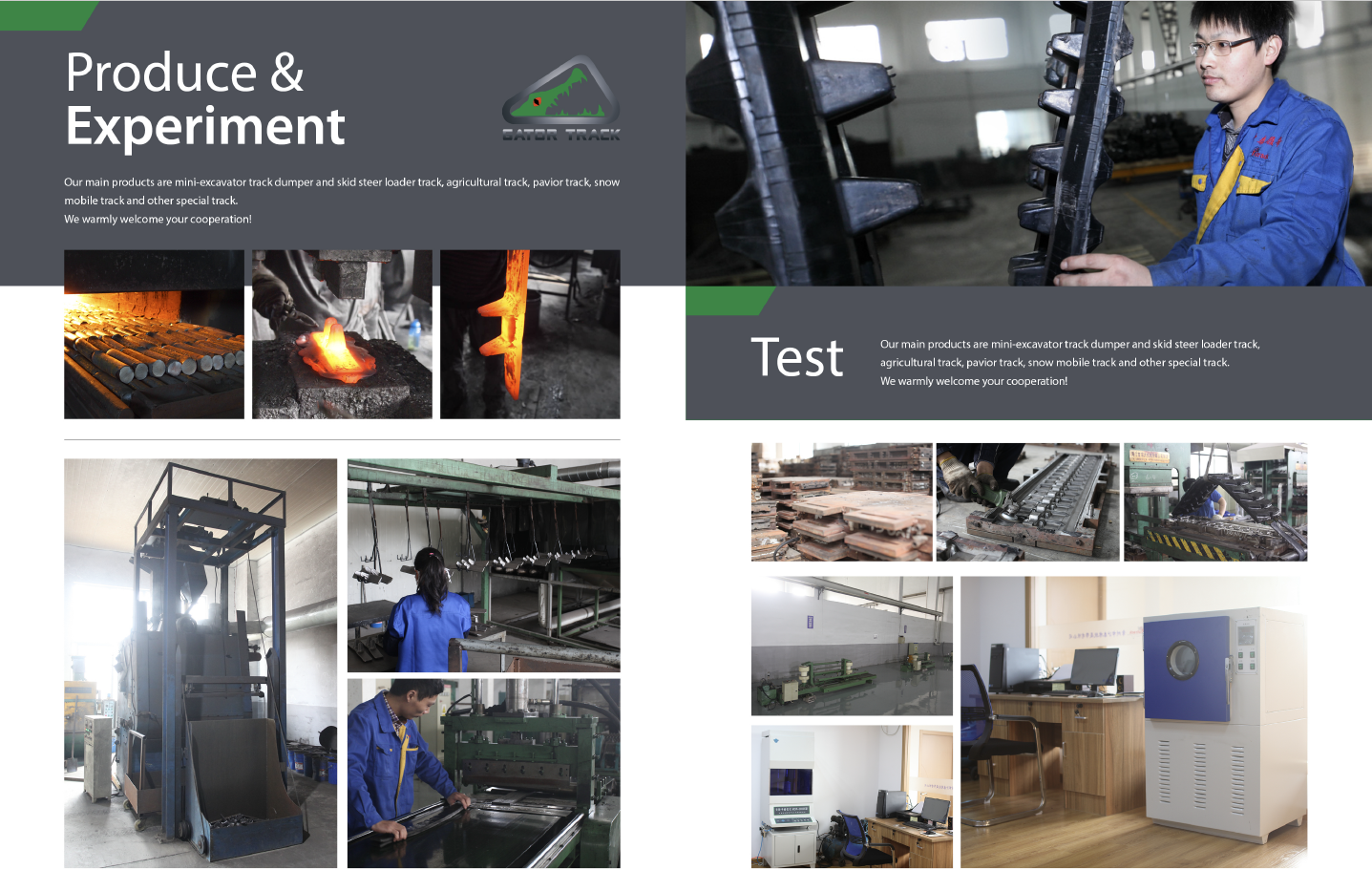

Why choose us?

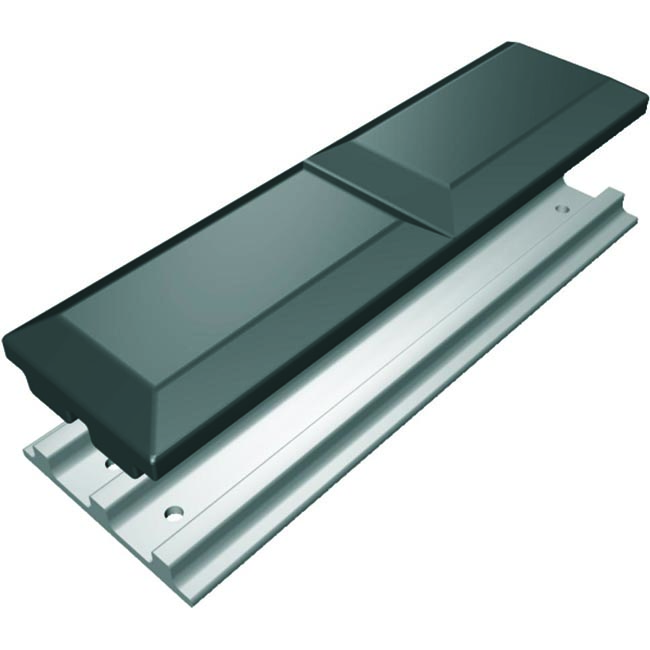

HXP500HT EXCAVATOR PADS

The HXP500HT track pad excavators are the best option for any construction project since they are made with premium materials and precise engineering, enabling them to endure large weights and extreme pressure. These pads offer the stability and traction required to finish any task, no matter how big or small. They are ideal for both delicate excavation work and large-scale earthmoving projects.

Because the HXP500HT Excavator Pads are made to particularly fit a variety of excavator types, they are an adaptive and versatile addition to any fleet of heavy equipment. These pads may be swiftly and easily integrated into your current machinery, eliminating downtime and improving productivity thanks to their simple installation method.

These pads are not only incredibly strong and long-lasting, but they are also made with the comfort and safety of the operator in mind. The HXP500HT Excavator Pads' sophisticated architecture lessens vibrations, giving the operator a smoother and more pleasant ride. Additionally, their non-slip surface offers better grip, lowering the possibility of mishaps and guaranteeing a safe working environment.

These pads also require little upkeep, which lowers overall operating expenses and results in reduced downtime and greater production. Every day, you can be sure that your equipment will operate at peak efficiency thanks to the HXP500HT Excavator Pads.

The Importance of Excavator Rubber Track Pads

Excavator rubber track pads of superior quality are made to resist the enormous loads and extreme pressure needed for excavation activity. They are constructed with a premium rubber compound that is resistant to abrasion, impact, and environmental conditions. Excavator track pads of poor quality will break down more quickly, increasing maintenance expenses and downtime. On the other hand, over time, purchasing high-quality rubber matting for your excavator can boost output, efficiency, and overall cost savings.

Reducing ground disturbance is one of the key benefits of rubber pads for excavators. Rubber mat substitutes for excavators are kinder to sensitive surfaces like concrete, asphalt, and landscaping than steel mats are. Because of this, they're perfect for construction, landscaping, and road building projects where maintaining the ground is essential. Rubber track pads on the excavator also contribute to noise reduction, which makes the equipment less harmful to the environment and less annoying to the surrounding region.

Excavator track pads selection should take your excavator's unique needs and the kind of work it will be doing into account. Features like tread pattern, track thickness, and breadth may vary depending on the project. To guarantee optimum performance and safety, excavator track pads require routine maintenance and inspection. It is imperative to promptly attend to any indications of wear, damage, or excessive wear in order to avert future issues and any safety risks. Maintaining and caring for your excavator properly not only increases its overall efficiency and safety but also extends the life of its track pads.

Some Advantags

1. Sturdiness and resistance to wear

Because excavators are frequently utilized in a variety of tough situations while on the job, the track pads must be sufficiently durable and wear resistant to guarantee the excavator operates as intended. The majority of the time, our company's track pads are constructed from premium alloy materials, which can maintain strong wear resistance during extended usage and increase the excavator's service life.

2. Performance against corrosion

The excavator pads can corrode in some unique working conditions, like damp rooms or extremely corrosive work areas, which can shorten the excavator's service life and performance. Our company primarily manufactures track pads that are resistant to corrosion or have undergone anti-corrosion treatment, which effectively lessens the effects of corrosion on the track pads and increases their lifespan.

3. Resistance to bending and compression

The track pads of an excavator must have enough bending and compression resistance because they will be subjected to tremendous pressure and impact from the ground and working materials. Digger track pads are typically produced using rigid procedures and have a high level of stiffness and strength. They can guarantee the safe operation of excavators and sustain consistent performance in challenging operating conditions.

4. A vast array of uses

They can satisfy the needs of different excavators and are appropriate for a variety of diverse terrains and operating situations, including dirt, gravel, stone, and other sorts of surfaces. In addition, track shoes can lessen environmental harm to the ground, safeguard it, and guarantee that project construction proceeds without hiccups. It can save construction costs, increase the safety and operational effectiveness of excavators, safeguard the environment, and lessen ground damage.

Frequently Asked Questions

We do not have a certain quantity requirement to start, any quantity is welcome!

30-45 days after order confirmation for 1X20 FCL.

We usually ship from Shanghai.

Of course! We can customize logo products.

Of course, we can! Our engineers have over 20 years of experience in rubber products and can help design new patterns.