Key Features of Dumper Rubber Tracks

Flexibility and Adaptability

Dumper rubber tracks excel in flexibility and adaptability, making them a preferred choice for various construction environments. You will find that these tracks can easily conform to different terrains, whether it's soft ground, mud, or gravel. This flexibility allows your machinery to maintain a firm grip and stable movement, even on uneven surfaces. The continuous surface and high contact area of rubber tracks provide superior maneuverability, which is crucial when navigating tight spaces or complex construction sites.

Durability and Longevity

When it comes to durability, dumper rubber tracks stand out due to their robust construction. These tracks are made from high-quality rubber compounds reinforced with steel cables or fibers. This design ensures they can withstand the rigors of heavy-duty applications and rough terrain. You benefit from their long service life, as they resist wear and tear effectively. The use of non-recycled rubber and advanced manufacturing techniques further enhances their longevity, reducing the need for frequent replacements and lowering maintenance costs.

Superior Traction

One of the most significant advantages of dumper rubber tracks is their superior traction. These tracks provide excellent grip on various surfaces, including slippery or uneven terrains. This feature is particularly beneficial in construction settings where maintaining control and stability is essential. The innovative tread designs and durable rubber compounds used in these tracks ensure optimal performance, allowing you to operate machinery with confidence and precision. By reducing ground pressure, rubber tracks also minimize surface damage, aligning with eco-friendly construction practices.

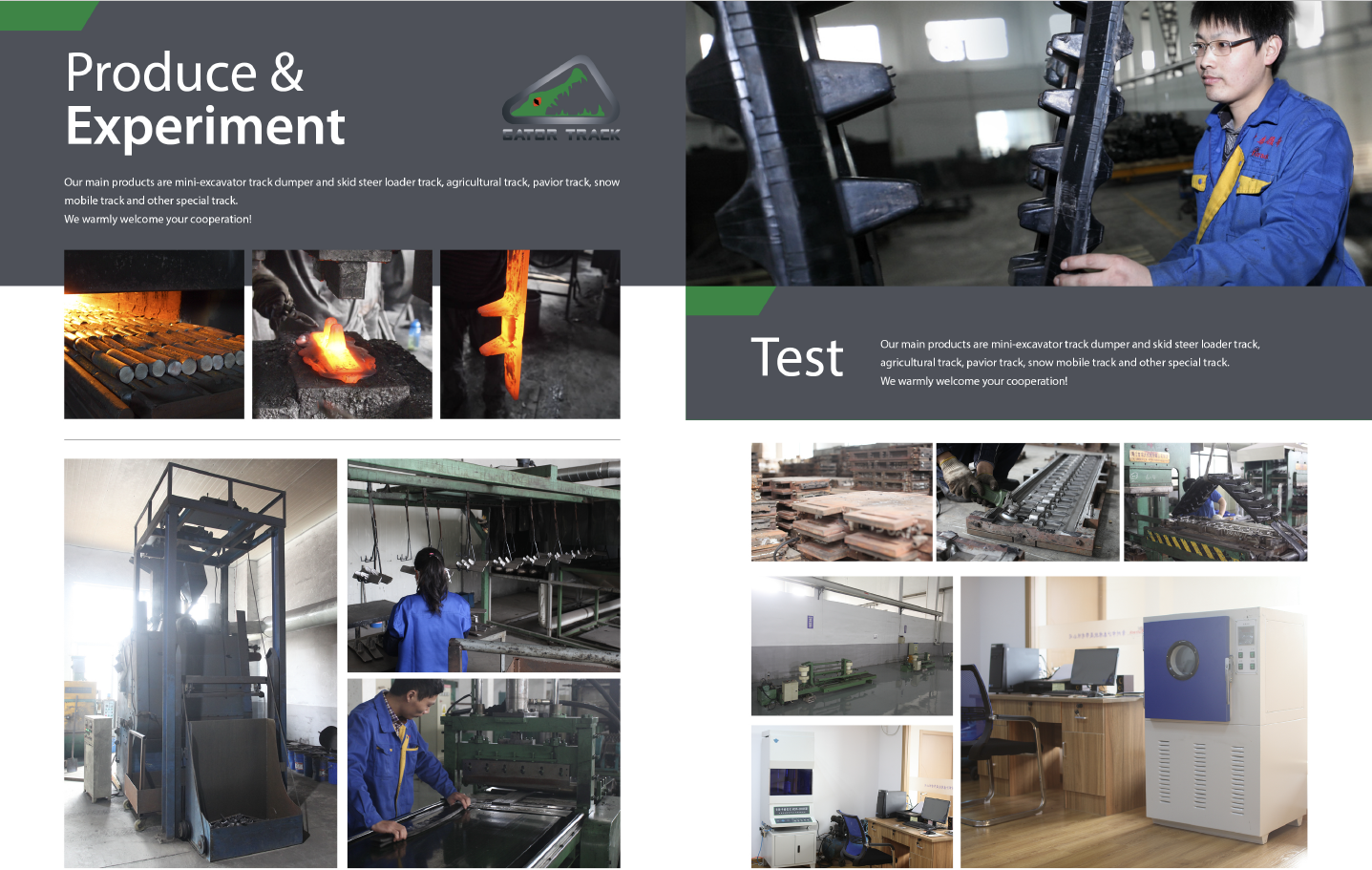

Why choose us?

We have strong technical strength and complete testing methods to monitor the entire process from raw materials to finished products leaving the factory. Complete testing equipment, a sound quality assurance system and scientific management methods are the guarantee of the quality of our company's products.

Currently we have 10 vulcanization workers, 2 quality management personnel, 5 sales personnel, 3 management personnel, 3 technical personnel, and 5 warehouse management and cabinet loading personnel.

Advantages Over Other Track Types

Comparison with Steel Tracks

When you compare dumper rubber track to steel tracks, several key differences emerge. Rubber tracks excel in reducing vibration and noise, making them ideal for urban or residential construction sites. This feature not only enhances operator comfort but also minimizes noise pollution, which is crucial in populated areas. In contrast, steel tracks are heavier and often generate more noise during operation.

Rubber tracks also offer superior surface protection. They distribute the weight of the machinery more evenly, reducing ground pressure and preventing damage to sensitive surfaces. This makes them particularly suitable for projects where preserving the integrity of the ground is essential. Steel tracks, while providing excellent traction and stability, can cause significant surface damage due to their weight and rigidity.

Moreover, rubber tracks are easier to install and maintain. They require less frequent maintenance compared to steel tracks, which are known for their durability in harsh conditions but demand more upkeep. This ease of maintenance translates to less downtime and increased productivity on construction sites.

Cost-Effectiveness

Dumper rubber tracks present a cost-effective solution for construction projects. Their initial purchase price is generally lower than that of steel tracks, making them an attractive option for budget-conscious projects. Additionally, rubber tracks contribute to reduced fuel consumption. Their lighter weight and design allow machinery to operate more efficiently, leading to fuel savings over time.

The longevity of rubber tracks, enhanced by advanced rubber compounds, further adds to their cost-effectiveness. You will find that they require fewer replacements, which reduces long-term operational costs. This durability, combined with lower maintenance needs, ensures that rubber tracks provide excellent value for money.

Durability and Maintenance

Common Issues and Solutions

When using dumper rubber track, you might encounter some common issues. These can include wear and tear, punctures, and track misalignment. Understanding these problems and knowing how to address them can significantly extend the lifespan of your tracks.

1. Wear and Tear: Over time, rubber tracks can experience wear due to constant use on rough terrains. To mitigate this, regularly inspect your tracks for signs of excessive wear. Replace them when the tread depth becomes too shallow to ensure optimal traction and safety.

2. Punctures: Sharp objects on construction sites can puncture rubber tracks. To prevent this, clear debris from the work area whenever possible. If a puncture occurs, patch kits are available that allow you to repair minor damage quickly.

3. Track Misalignment: Misalignment can cause uneven wear and reduce track life. Regularly check the alignment of your tracks and adjust them as needed. Proper alignment ensures even distribution of weight and reduces unnecessary strain on the tracks.

Maintenance Best Practices

Maintaining dumper rubber tracks involves several best practices that can enhance their durability and performance. By following these guidelines, you can maximize the efficiency and lifespan of your tracks.

·Regular Cleaning: Keep your tracks clean by removing mud, dirt, and debris after each use. This prevents buildup that can lead to premature wear and damage.

·Proper Tensioning: Ensure that your tracks are correctly tensioned. Tracks that are too tight or too loose can cause unnecessary stress and lead to faster deterioration. Follow the manufacturer's guidelines for the correct tension settings.

·Routine Inspections: Conduct routine inspections to identify any signs of damage or wear. Look for cracks, cuts, or exposed steel cords. Early detection allows for timely repairs, preventing more significant issues down the line.

·Lubrication: Lubricate the moving parts of your machinery regularly. This reduces friction and wear, contributing to smoother operation and longer track life.

By adhering to these maintenance practices, you ensure that your dumper rubber tracks remain in excellent condition, providing reliable performance across various construction environments.

Enhanced Operational Efficiency

Dumper rubber tracks significantly boost operational efficiency on construction sites. You will notice that these tracks provide excellent traction and stability, allowing machinery to move swiftly across various terrains. This capability reduces the time spent navigating challenging surfaces, enhancing productivity. The design of rubber tracks minimizes rolling resistance, which optimizes fuel efficiency. As a result, machines equipped with rubber tracks consume less fuel, leading to cost savings and extended operational hours.

Rubber tracks also offer superior maneuverability. They allow for precise turns and zero-radius turns, which are crucial in tight or constricted spaces. This feature ensures that you can operate machinery with greater control and accuracy, reducing the risk of accidents or damage to the site. The versatility of rubber tracks makes them ideal for urban construction projects where space is limited and precision is paramount.

Environmental and Safety Benefits

Rubber tracks contribute to environmental stewardship by reducing ground pressure and minimizing soil compaction. This feature is particularly beneficial in sensitive environments where preserving the integrity of the ground is essential. By distributing the weight of the machinery more evenly, rubber tracks prevent ecological damage and align with eco-friendly construction practices. You will find that this aspect is increasingly important as regulations promoting sustainable construction become more stringent.

In addition to their environmental benefits, rubber tracks enhance safety on construction sites. They reduce noise pollution due to their quieter operation compared to steel tracks. This reduction in noise creates a more comfortable working environment and is especially advantageous in urban or residential areas. Furthermore, the stability provided by rubber tracks decreases the likelihood of machinery tipping over, ensuring a safer workplace for operators and other personnel.

By choosing rubber track dump truck, you not only improve the efficiency and effectiveness of your construction operations but also contribute to a safer and more environmentally responsible industry.