China Wholesale Rubber Track Factory Manufacturer - Rubber Tracks 400-72.5KW Excavator Tracks – Gator Track

China Wholesale Rubber Track Factory Manufacturer - Rubber Tracks 400-72.5KW Excavator Tracks – Gator Track Detail:

Product Detail

Our 400-72.5KW conventional excavator rubber tracks are for use with undercarriages of machinery specifically designed to operate on rubber tracks. Conventional rubber tracks do not make contact with the metal of the equipment’s rollers while in operation. No contact equals increased operator comfort. Another advantage of conventional rubber tracks is the heavy equipment roller contact will ONLY occur when aligning the conventional rubber tracks to prevent roller derailment.

Our rubber tracks are made from specially formulated rubber compounds that resist cutting and tearing. Our tracks have all-steel links that are designed with exact guide specifications to fit your machine and ensure smooth equipment operation. The steel inserts are drop-forged and are dipped in a special bonding adhesive. By dipping the steel inserts rather than brushing them with adhesive there is a much stronger and more consistent bond within; This ensures a more durable track.

Purchasing rubber tracks for your equipment from us can increase the versatility of the functions that your machine can perform. In addition, replacing your old rubber tracks with new ones from ensures peace of mind that you won’t have machine downtime – saving you money and getting your job done on time.ronger and more consistent bond within; This ensures a more durable track.

The Feature of Rubber Track

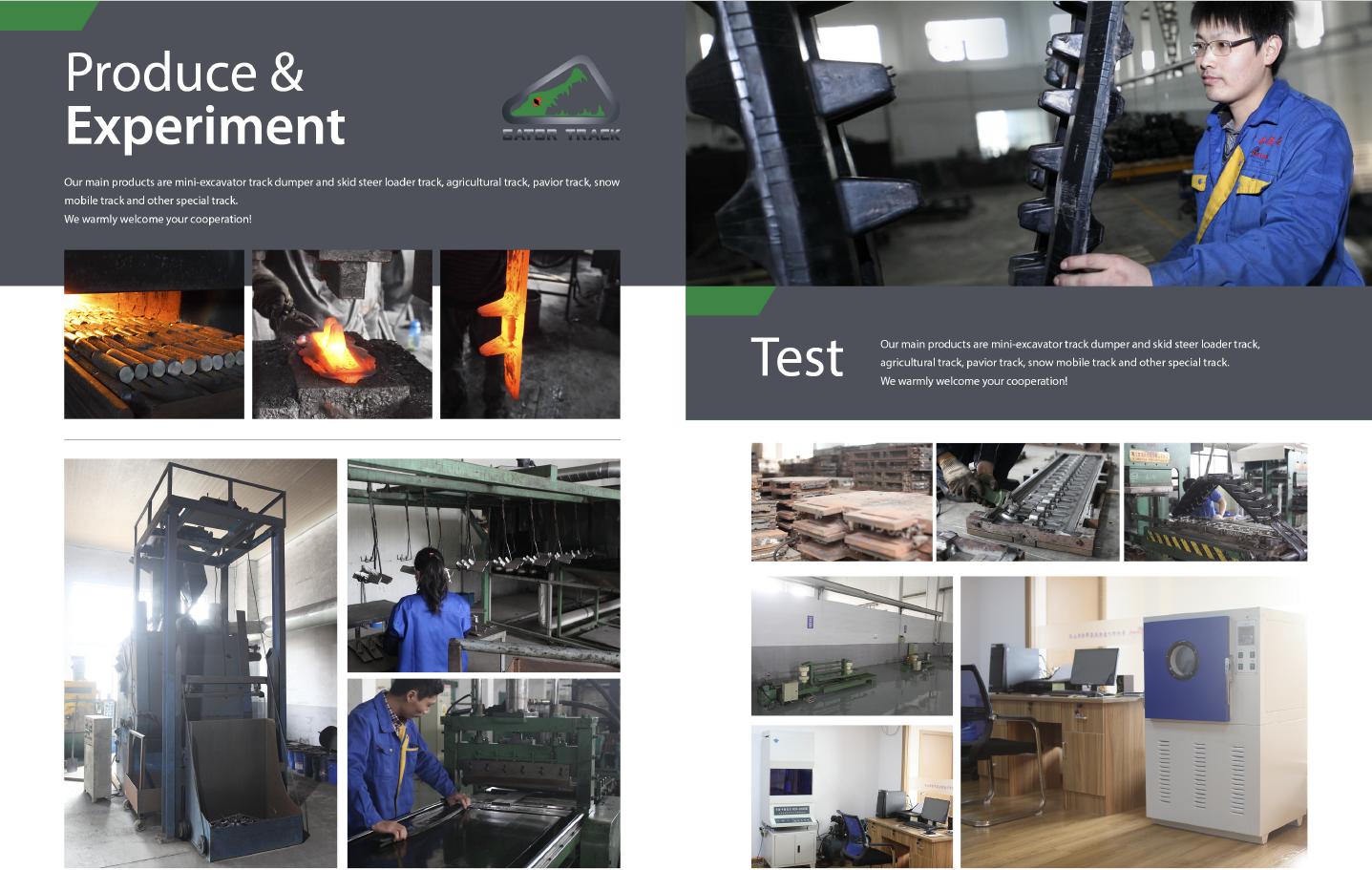

Production Process

Raw Material: Natural rubber / SBR rubber/ Kevlar fiber / Metal / Steel cord

Step: 1.Natural rubber and SBR rubber mixed together with special ratio then they will be formed as

rubber block

2.Steel cord coverd with kevlar fibe

3.Metal parts will be injected with special compounds which can improve their performance

3.The excavator track pads, kevlar fiber cord and metal will be put on the mould in ordered

4.The mould with materials will be deliver in to the big production machine, the machinery use high temperature

and high volume press to make all the material together.

Production Process

Why Choose Us

Gator Track has built enduring and solid working partnerships with many well-known companies in addition to aggressively growing the market and consistently extending its sales channels. Currently, the company’s markets include the United States, Canada, Brazil, Japan, Australia, and Europe (Belgium, Denmark, Italy, France, Romania, and Finland).

We have pallets+black plastic wrapping around packages for LCL shipping goods.For full container goods, usually bulk package.

FAQs

1. Which port is closest to you?

We usually ship from Shanghai.

2. If we provide samples or drawings, can you develop new patterns for us?

Of course, we can! Our engineers have over 20 years of experience in rubber products and can help design new patterns.

3. What information should I offer to confirm a size?

A1. Track Width * Pitch Length * Links

A2. Your machine type (Like Bobcat E20)

A3. Quantity, FOB or CIF price,port

A4. If it is possible, pls also provide with pictures or drawing for double checking.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for China Wholesale Rubber Track Factory Manufacturer - Rubber Tracks 400-72.5KW Excavator Tracks – Gator Track , The product will supply to all over the world, such as: Belgium, Croatia, Belgium, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.